Identifying Your Distributor Type: Front-Mount or Side-Mount?

The first step in tackling your Ford 8N's distributor issues is identifying its type. This is crucial because front- and side-mounted distributors differ significantly, affecting parts compatibility and repair procedures. While serial numbers can help, they're often difficult to read due to wear. A more reliable method is visual inspection. For further assistance with Ford 8N ignition systems, check out this helpful resource on Ford 8N firing order.

Locate the Serial Number: Begin by attempting to locate the serial number. It's typically stamped on a plate near the steering column or the engine block. However, don't solely rely on this as it may be illegible.

Visual Inspection: Open the hood and examine the engine. Is the distributor mounted on the front of the engine or on the side? This is the most reliable method for determining the distributor type.

Front-Mounted: Typically found on tractors with serial numbers below 263844, indicating an earlier production date.

Side-Mounted: Generally found on tractors with serial numbers above 263844, indicating a later production date.

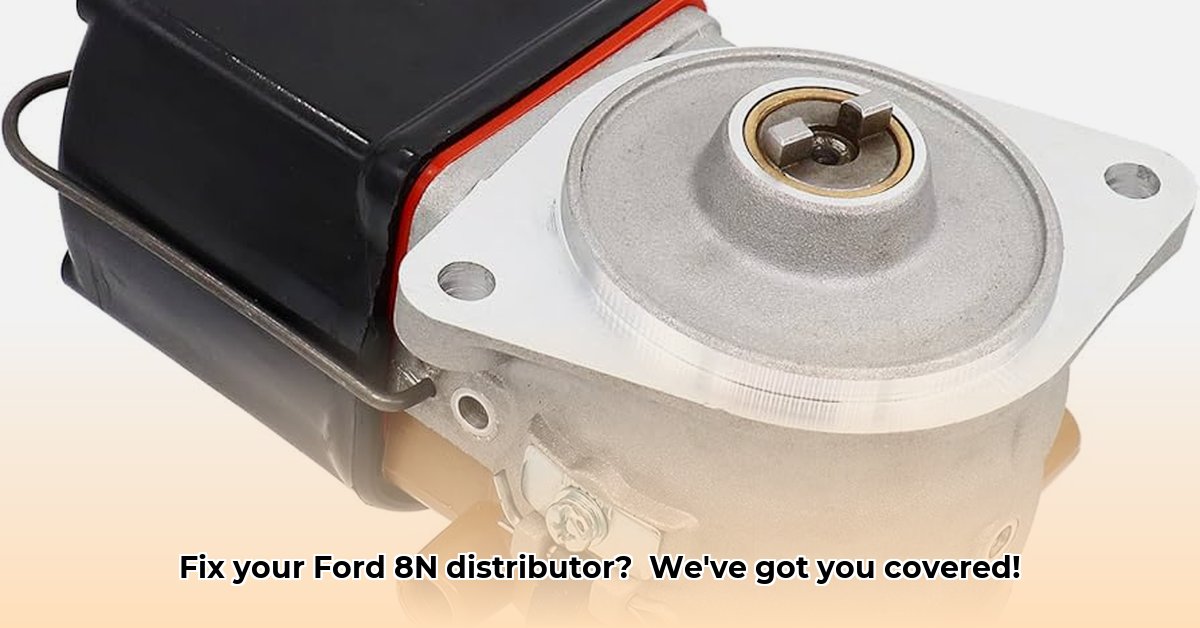

Knowing which type you have is essential for selecting correct replacement parts and following the appropriate repair procedures. A picture would greatly aid in visual identification here, showing both front and side mounting locations clearly.

Parts Breakdown and Sourcing: Knowing Your Distributor's Anatomy

Understanding your distributor's components is crucial for effective troubleshooting and repair. Each part plays a vital role in the ignition system.

Distributor Cap: (The topmost part of the distributor; directs high voltage to the correct spark plug.) Inspect for cracks or carbon deposits which can lead to misfires.

Rotor: (The rotating component inside the cap; distributes the high voltage to the spark plugs.) Wear or damage can cause ignition timing issues.

Points: (Two metal contacts that open and close to create the spark. They're mechanical and wear down over time.) Worn points are a common cause of starting problems or misfires. Regular replacement is essential.

Condenser: (A small capacitor that smooths out the electrical current; protects the points from damage.) A failing condenser can lead to premature point wear or ignition problems.

Shaft: (The rotating part that drives the points and rotor. A damaged shaft can lead to misalignment and timing problems.) Damage to this requires specialized knowledge or professional help.

Sourcing Parts: Original equipment manufacturer (OEM) parts from Ford are preferred for optimal performance but can be expensive. Aftermarket parts are widely available and often more affordable but always verify compatibility with your distributor type before purchasing. Yesterday's Tractors (https://www.yesterdaystractors.com/) is a valuable resource for both OEM and aftermarket parts.

Troubleshooting Common Issues: Diagnosing Ignition Problems

A malfunctioning distributor can manifest in various ways. A methodical approach to troubleshooting is key:

Check the Basics: Before investigating the distributor, ensure the fuel tank is full, spark plugs are connected and in good condition, and the battery is charged. These simple checks often reveal the root cause.

Visual Inspection: Carefully inspect the distributor cap and rotor for cracks, burns, or deposits. Clean any visible dirt or grime.

Points and Condenser Testing: Measuring the point gap and condenser capacitance requires a multimeter (a basic electrical testing tool). This step helps to distinguish between faulty points and a failing condenser. If you are not comfortable with this task, seek professional help.

Ignition Coil Check: In some cases, coil failure might mimic distributor problems. Testing the coil's resistance is important to rule out this possibility. Similarly, a faulty coil wire could also mimic a faulty distributor.

Wiring inspection: Loose, damaged, or corroded wiring can severely compromise the entire system. Always double-check all connections before replacing components.

Addressing these potential issues systematically increases your chances of correctly identifying and fixing the problem.

Installation/Replacement Guide: Precision and Patience are Key

Replacing a distributor is a precise task best left to those with mechanical experience and the right tools. Incorrect installation can lead to significant engine damage affecting more than just the ignition system. Here are some generalized steps, but a comprehensive guide exceeds the scope of this article.

Careful Removal: Document the old distributor’s orientation and wiring before removing it. Photographs are highly recommended.

Precise Installation: The new distributor should be precisely aligned and securely mounted.

Wiring: Reconnect all wires based on the documentation you created during removal.

Ignition Timing Adjustment: After installation, the ignition timing must be checked and adjusted using a timing light.

If you're unsure about any of these steps, consulting a qualified mechanic is highly recommended. Improper installation can cause irreversible damage.

Maintenance and Preventative Care: Extending Your Distributor's Life

Regular maintenance significantly extends the life of your distributor and minimizes the risk of failure.

| Component | Recommended Replacement Interval | Reason |

|---|---|---|

| Points | Every 1-2 years | Wear and tear; vital for spark generation |

| Condenser | Every 1-2 years | Prevents point damage; ensures reliable ignition |

| Distributor Cap | As needed (cracks/damage) | Cracks lead to arcing and poor performance |

| Rotor | As needed (wear/damage) | Wear causes poor spark distribution |

Remember, these intervals are guidelines and may vary based on usage. Regular visual inspection is key in determining when parts need to be replaced.

12V Conversion (Optional): A Significant Upgrade

Upgrading your 8N to a 12V system offers several advantages, including easier starting and a stronger spark. However, it's a complex project requiring specialized knowledge and potentially additional parts. This conversion is beyond the scope of this guide. Consult specialized resources and professionals before attempting a 12V conversion.

Resources: Where to Find More Information

Yesterday's Tractors: (https://www.yesterdaystractors.com/) A valuable resource for parts and information on Ford 8N tractors.

Online Forums: Search for Ford 8N forums where you can find troubleshooting advice and tips from experienced owners.

Original Ford Manuals: If possible, locate original Ford technical manuals for your tractor's model year. These provide the most detailed and accurate information.

This guide aims to provide practical guidance on your Ford 8N's distributor. Remember, safety and precision are paramount when working on your tractor.